Chemical formula: Na5P3O10

Molecular weight: 367.86

Properties: White powder or granules, easily soluble in water. According to the application and processing requirements, we can provide products of various specifications such as different apparent densities (0.5-0.9g/cm3), different solubilities (10g, 20g/100ml water), instant sodium tripolyphosphate, large-particle sodium tripolyphosphate, etc.

Uses:

1.In the food industry, it is mainly used as a quality improver for canned food, dairy products, fruit juice drinks and soy milk; a water retainer and tenderizer for meat products such as ham and luncheon meat; it can retain water, tenderize, expand and bleach in the processing of aquatic products; it can soften the skin of broad beans in canned broad beans; it can also be used as a water softener, chelating agent, PH regulator and thickener, as well as in the beer industry.

2. In the industrial field, it is widely used in detergents as an auxiliary agent, soap synergist and to prevent bar soap from crystallizing and blooming, industrial water softener, leather pretanning agent, dyeing auxiliary, oil well mud control agent, oil pollution prevention agent for papermaking, effective dispersant for the treatment of suspensions such as paint, kaolin, magnesium oxide, calcium carbonate, etc., and ceramic degumming agent and water reducer in the ceramic industry.

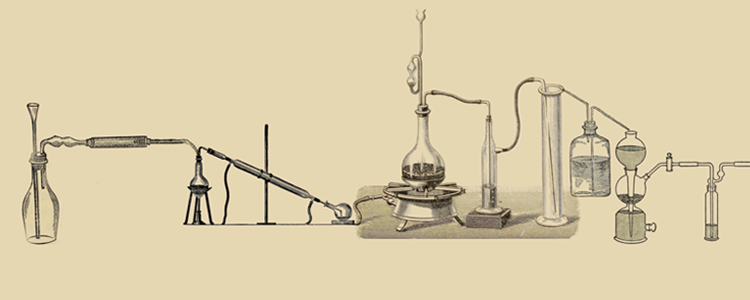

The traditional preparation method of sodium polyphosphate is to neutralize hot phosphoric acid with a mass fraction of 75% H3PO4 with a soda ash suspension to obtain a neutralized slurry with a Na/P ratio of 5:3, and keep it warm at 70℃~90℃; then spray the obtained slurry into a polymerization furnace for dehydration at high temperature, and condense it into sodium tripolyphosphate at about 400℃. This traditional method not only requires expensive hot phosphoric acid, but also consumes a lot of heat energy; in addition, when preparing the slurry by neutralization, it is necessary to heat and remove CO2, and the process is complicated. Although chemically purified wet phosphoric acid can be used to replace hot phosphoric acid to produce sodium tripolyphosphate, due to the high content of metal iron in wet phosphoric acid, it is difficult to meet the quality requirements of current sodium tripolyphosphate products, and it is also difficult to meet the indicators specified in national standards.

At present, people have studied some new production processes of sodium tripolyphosphate, such as Chinese patent application No. 94110486.9 "A method for producing sodium tripolyphosphate", No. 200310105368.6 "A new process for producing sodium tripolyphosphate", No. 200410040357.9 "A method for producing sodium tripolyphosphate by dry-wet comprehensive method", No. 200510020871.0 "A method for producing sodium tripolyphosphate by Glauber's salt double decomposition method", 200810197998.3 "A method for producing sodium tripolyphosphate and by-producing ammonium chloride", etc.; although these technical solutions have their own characteristics, most of them are to change the neutralization raw materials.

Method for producing sodium tripolyphosphate using crude sodium pyrophosphate

The crude sodium pyrophosphate first enters the salt washing tank to remove most of the sodium chloride, and then enters the plate and frame filter press for primary filtration. The filter cake contains a large amount of sodium pyrophosphate, and the mass concentration of sodium chloride is less than 2.5%. Then, the solution is heated to 85°C in the dissolution tank with steam for stirring and dissolving. Sodium sulfide is added during dissolution to remove metal ions. The insoluble matter is impurities such as copper hydroxide. It is filtered again for the second time. The filtrate is a sodium pyrophosphate solution. Activated carbon is added to the filtrate to remove pigments, phosphoric acid is added to acidify and accelerate dissolution, and finally liquid alkali is added to adjust the pH value to 7.5-8.5 to prepare a refined liquid.

A part of the refined liquid is directly used in the sodium tripolyphosphate neutralization liquid preparation section, and the other part of the refined liquid is pumped into the DTB crystallizer. The refined liquid in the DTB crystallizer is cooled in the heat exchanger by a forced circulation pump and 5°C water sent by the chiller. When the solution temperature drops to 15°C, it is crystallized into flocs and then transported to the high-level tank and centrifuged into the centrifuge for centrifugal separation to obtain sodium pyrophosphate crystals. The sodium pyrophosphate crystals are added to the neutralization liquid preparation section in the sodium tripolyphosphate production process and mixed with phosphoric acid and liquid caustic soda to prepare the neutralization liquid as the raw material for the production of sodium tripolyphosphate. The above-mentioned brine is returned to wash the crude sodium pyrophosphate; when the sodium chloride content in the brine reaches saturation, the brine is pumped into the buffer tank, and the brine in the buffer tank is pumped into the sodium tripolyphosphate tail gas duct jacket to exchange heat with the high-temperature tail gas. The brine after heat exchange returns to the buffer tank for spray evaporation.

Contact:

Beijing Shipuller Co., Ltd

WhatsApp:+86 18311006102

Web: https://www.yumartfood.com/

Post time: Nov-11-2024