As a leading sushi nori manufacturer, we take immense pride in the meticulous production process that transforms ocean-harvested seaweed into the delicate, flavorful sheets of roasted nori cherished by sushi lovers worldwide. Our commitment to quality, sustainability, and innovation is at the heart of everything we do. In this article, we will take you through each step of our production process, showcasing our expertise and dedication to delivering the finest roasted nori.

1. Sourcing Quality Seaweed

The journey of producing exceptional roasted nori begins with sourcing high-quality seaweed. As a sushi nori manufacturer, we carefully select the best species of seaweed, primarily *Porphyra*, known for its rich umami flavor and nutritional benefits. We partner with trusted seaweed farmers who adhere to sustainable farming practices, ensuring that our raw materials are harvested responsibly. This commitment to ethical sourcing not only supports local communities but also guarantees that we start with the finest seaweed available.

2.Hand-Harvesting Techniques

Once the seaweed reaches its peak growth, our skilled farmers hand-harvest the plants with great care. This traditional method minimizes damage to the seaweed and its surrounding environment, allowing for optimal regrowth. As a sushi nori manufacturer, we understand the importance of preserving the natural ecosystem while ensuring that we obtain the freshest seaweed possible. Hand-harvesting also allows us to select only the highest quality seaweed for our production process.

3. Thorough Washing and Preparation

Upon arrival at our production facility, the freshly harvested seaweed undergoes a rigorous washing process. We use advanced techniques to remove any impurities, sand, or salt that may have accumulated during harvesting. This step is crucial in maintaining the quality of the seaweed. After washing, the seaweed is carefully laid out to drain excess water, ensuring it is ready for the next stage of production.

4. Drying to Perfection

Once the seaweed is adequately drained, it is subjected to a drying process. Depending on the desired quality and texture, we may employ traditional sun-drying methods or advanced drying technologies. The goal is to reduce moisture content while preserving the vibrant color and flavor of the seaweed. As a sushi nori manufacturer, we meticulously control the drying conditions to ensure that the seaweed retains its natural characteristics, resulting in a superior final product.

5.Grinding for Consistency

After drying, the seaweed is ground into small pieces. These small pieces serve as the foundation for producing various nori products, including our beloved roasted nori sheets. Our expertise in grinding techniques allows us to achieve a consistent texture, which is essential for the quality of the final product. As a sushi nori manufacturer, we know that the right consistency contributes significantly to the overall taste and mouthfeel of the roasted nori.

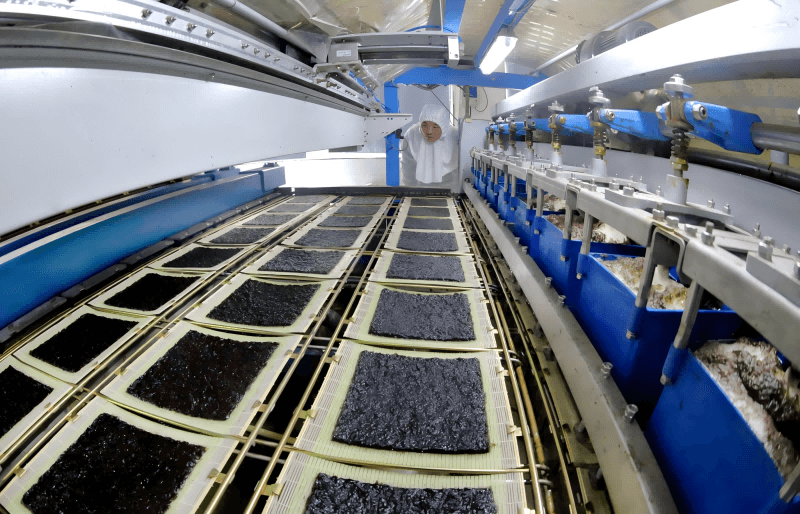

6.Forming Nori Sheets

The next step in our production process is forming the nori sheets. The ground seaweed is mixed with water to create a slurry, which is then spread evenly onto a conveyor belt. This machine forms thin sheets of seaweed, which are pressed to remove excess water and ensure uniform thickness. Attention to detail is paramount during this stage, as the thickness and texture of the nori sheets greatly influence the final product. Our experience as a sushi nori manufacturer allows us to achieve the perfect balance between thinness and strength.

7. Roasting for Flavor

Once the nori sheets are formed, they are ready for roasting. This critical step involves passing the sheets through a controlled roasting chamber, where they are exposed to heat. Roasting enhances the flavor of the nori, imparting the characteristic umami taste that is essential for sushi and other culinary creations. As a sushi nori manufacturer, we pride ourselves on our expertise in roasting techniques, ensuring that each sheet is evenly roasted to achieve a consistent flavor profile.

8.Stringent Quality Control

Quality control is a cornerstone of our production process. Each batch of roasted nori undergoes rigorous testing to ensure it meets our high standards for taste, texture, and appearance. We conduct sensory evaluations, laboratory tests, and visual inspections to guarantee that our customers receive only the best products. Our commitment to quality as a sushi nori manufacturer is unwavering, and we continuously strive to exceed the expectations of our clients.

9. Thoughtful Packaging and Distribution

Once our roasted nori has passed all quality checks, it is carefully packaged to preserve freshness and flavor. We use high-quality, food-safe packaging materials that protect the nori from moisture and light, ensuring it remains crispy and delicious upon reaching our customers. As a sushi nori manufacturer, we understand the importance of timely distribution, and we work diligently to ensure that our products are delivered promptly to our clients.

Conclusion

In conclusion, the production process of roasted nori is a blend of art and science, requiring expertise, dedication, and a passion for quality. As a leading sushi nori manufacturer, we take pride in every step of this journey, from sourcing the finest seaweed to delivering exceptional roasted nori to our customers. Our commitment to excellence ensures that you receive only the highest quality products, perfect for sushi and a variety of culinary applications. Trust us as your sushi nori manufacturer, and experience the difference that quality makes in your dishes.

Contact

Beijing Shipuller Co., Ltd.

WhatsApp: +86 136 8369 2063

Web: https://www.yumartfood.com/

Post time: Aug-06-2024